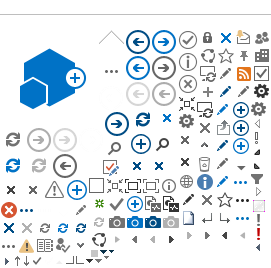

Solution Hole

With genuine TennantTrue brushes, cleaning solution flows through holes in the machine drive plug and brush drive adaptor, then moves across the working face of the brush. When solution holes are obstructed, a significant amount of cleaning solution by-passes the brush – resulting in poor cleaning performance, wasted cleaning solution, and additional labor costs. Brushes not designed for Tennant machines waste water, cleaning solution, and hinder your operator's performance. TOP

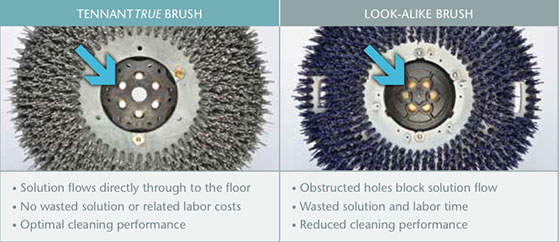

Drain Holes

TennantTrue brushes include drain holes to help clear the drive plug of debris. Will-fit brushes without drain holes allow grit and grime to collect in between the drive plug and brush adaptor. This can accelerate wear and damage to the drive plug over the life of the brush. TOP

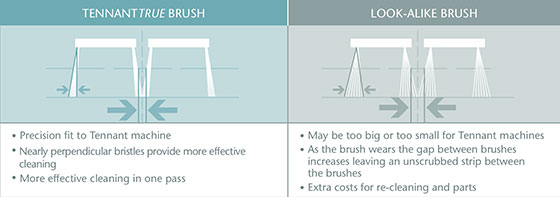

Flare Diameter

Tennant designs and manufactures each brush for a precision fit to the machine. Will-fit brushes not designed specifically for Tennant machines result in a wrong fit for a specific machine or application. This can cause brush-to-brush interference or leave unclean floor spaces.

Will-fit brush filaments are set at an angle to the cleaning surface. As the bristles wear, debris is often left on the floor between the brush cleaning paths. Tennant brushes are set nearly perpendicular to the cleaning surface to help extend brush life and minimize re-cleaning. TOP

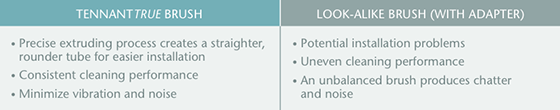

Manufacturing Standards

TennantTrue brush tubes are manufactured to the industry's tightest standards for straightness, roundness, wall thickness, and fit. These characteristics ensure smooth operation of the brush and prevent excessive wear and strain on the various machine components. Because the spline is extruded throughout the entire brush tube length this helps ensure balance to the brush resulting in consistent cleaning performance. TOP

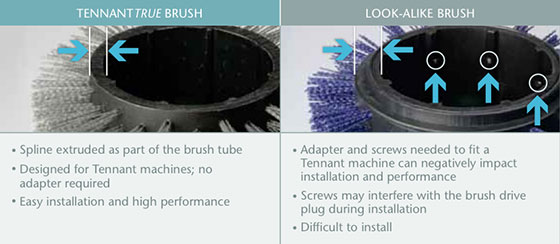

Spline Drive

The spline on each TennantTrue brush tube is extruded as part of the brush manufacturing process to ensure the best fit on Tennant machines. Will-fit brushes require adapters with screws that can negatively affect brush installation and performance. TOP

Brush Tube Diameter

TennantTrue brushes provide a maximum bristle length for the longest possible wear. Will-fit brushes that require an adaptor add weight to the overall brush and can compromise bristle length by up to 40 percent *. TOP

*Based on scrub brush when worn to ¾ inch bristle length

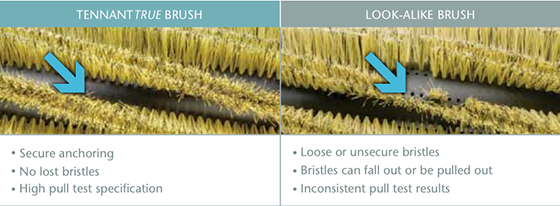

Bristle Anchoring

Tennant specifies a pull test measurement for bristle tufts to ensure they are securely anchored to the brush. Brush bristles work best and longest when they are anchored securely. Will-fit brushes often have poorly secured bristle tufts that can fall out or be pulled out when going over grates or other rough surfaces. TOP

TennantTrue Patented Brushes and Sand Wedge Brush

Tennant's patented sand wedge design contains the same amount of bristle material as high density brushes with distinctive gaps that perform a digging action. This design is most effective for heavy concentrations of sand and other fine materials found in foundries, bakeries, and cement plants. TOP

TennantTrue Window Brush (Sweeping Brush)

Tennant's patented sand wedge design contains the same amount of bristle material as high density brushes with distinctive gaps that perform a digging action. This design is most effective for heavy concentrations of sand and other fine materials found in foundries, bakeries, and cement plants. TOP

Side Brush

Side brushes have a round, flared design that reach into corners and around edges, pulling debris in front of the sweeper for pick-up by the main brush. Tennant specifies the flare angle that provides maximum reach without compromising stiffness. Will-fit brushes often use lower grade filament materials, causing bristles to deform and cleaning performance to decline after just a few uses. TOP